Wheel Manufacturer of Polyurethane

We produce various polyurethane wheels and rubber rollers.

Rubber/polyurethane rubber rollers, rollers, and wheel manufacturers.

Provide specific solutions for different industry environments.

Strict control of product quality in each production process is our guarantee for each product quality

We offer a wide range of cast-iron, steel, aluminum and other hubs. All hubs are machined inside our turning and machining centers. The finished hub will pass the inspection, including specification, material stress, concentricity, etc.

Clean the wheel core and remove the oil stain on the surface to obtain a clean surface and ensure the bonding effect of glue. Sand blasted for improved adhesion. Finally, the adhesive is applied to the rim surface.

Heat the hub and die, activate the adhesive on the hub surface, and cast the polyurethane material into the die on the rotary table by center point pouring to avoid air bubbles. Demould after curing for 30 minutes.

Post-sulphurization is the basic process of manufacturing. After demoulding, the wheels will be put into the curing chamber under the specified conditions. Polyurethane properties will remain stable and optimum until all chemical reactions are completed.

Our professional team provides high-quality wheel solutions worldwide.

We provide storage and logistics forklifts, AGV/AMR robots, stackers, shuttle trucks, and automated stereoscopic warehouses, Stocker, OHCV/OHT, High performance polyurethane wheels are provided for material handling equipment such as conveyors and AGV platform vehicles; Including drive wheels, load-bearing wheels, auxiliary wheels, tray rollers, and so on.

LEARN MORE >>

Logistics Handling

Polyurethane wheel for semiconductor and liquid crystal panel manufacturing is a high-tech customized product designed for extremely clean and stable environment. It is not only a "wheel", but also a key and active "pollution control element" in the clean room material handling system.

LEARN MORE >>

Semiconductor/liquid crystal panel manufacturing

The self-developed high-performance MDI polyurethane and NDI polyurethane materials are used to provide high durable polyurethane rubber covered wheels and rollers for the welding, coating and elevator of the automobile production line. They have large bearing capacity, high speed, no degumming risk, good reliability and durability, and will not cause the production to stop due to the quality problem of the wheels.

LEARN MORE >>

Automotive manufacturing

The polyurethane wheels of mining equipment are customized according to the needs of the mine, and the materials meet the use characteristics of the mine. The mine specific high-performance polyurethane independently developed by YDL has excellent properties such as high resilience and high tear strength, which can be used for diesel vehicles, battery vehicles and pneumatic monorail cranes.

LEARN MORE >>

Mining machinery

According to the special working conditions of amusement park equipment, we have developed a series of polyurethane wheels with high resilience, which can bring better experience and comfort, high tearing, strong weather resistance, hydrolysis resistance, aging resistance, good temperature resistance and high life, and are widely used in many amusement parks.

LEARN MORE >>

Amusement park equipment

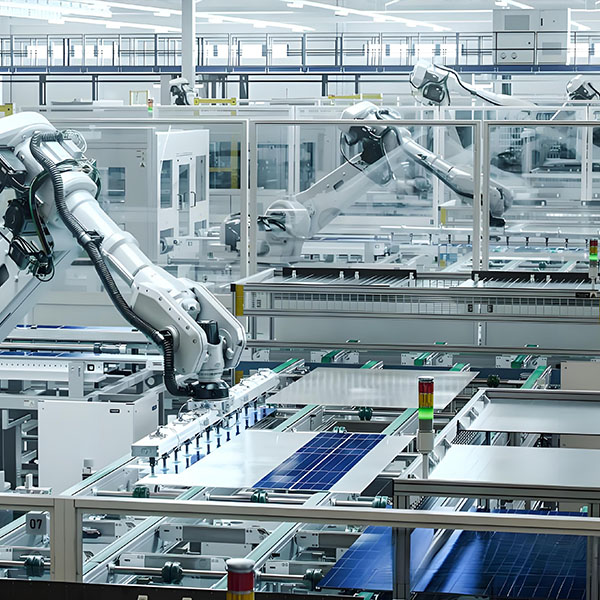

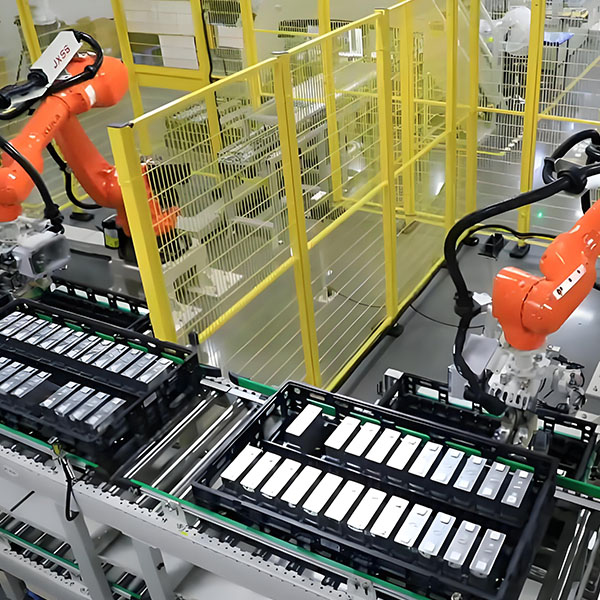

The production line of new energy products (lithium batteries, photovoltaic panels) uses polyurethane wheels, which are dust-free, anti-static and corrosion-resistant, and can well ensure the cleanness of the production line. The polyurethane material has very good wear resistance and impact resistance, and also has strong bearing capacity, which can well meet the needs of the new energy manufacturing production line.

LEARN MORE >>

New energy manufacturing

We provide customized polyurethane wheel solutions according to the actual needs of the three-dimensional parking garage, from material recommendation to product structure optimization. The polyurethane wheel of three-dimensional parking garage must have high strength, high elongation and high resilience, which can meet the use environment of high load.

LEARN MORE >>

Stereoscopic parking garage

Years of experience in the research and development of polyurethane and rubber materials

We produces and develops various mechanical wheels for customers, providing them with perfect system solutions for roller/shaft/wheel products...

Business Message

The technological competition between polyurethane wheels and rubber wheels has been ongoing for many years in the selection of wheels for forklifts and intelligent logistics equipment. With the increasing demands for efficiency, precision, and sustainability in modern warehousing environments, this competition has evolved from a simple cost comparison to a comprehensive consideration of system level performance.

2025-12-23READ ALL >>In order to enhance team cohesion and stimulate the spirit of struggle, on December 20th, YALIDE company organized a team building activity on Yinping Mountain with the theme of "YALIDE: Brave Climbing the Peak, Creating Brilliance" for employees in the Dongguan region. As the highest peak in Dongguan, Yinping Mountain has witnessed the unity, cooperation, and courage of YALIDE people with its majestic posture.

2025-12-22READ ALL >>