Customer Background

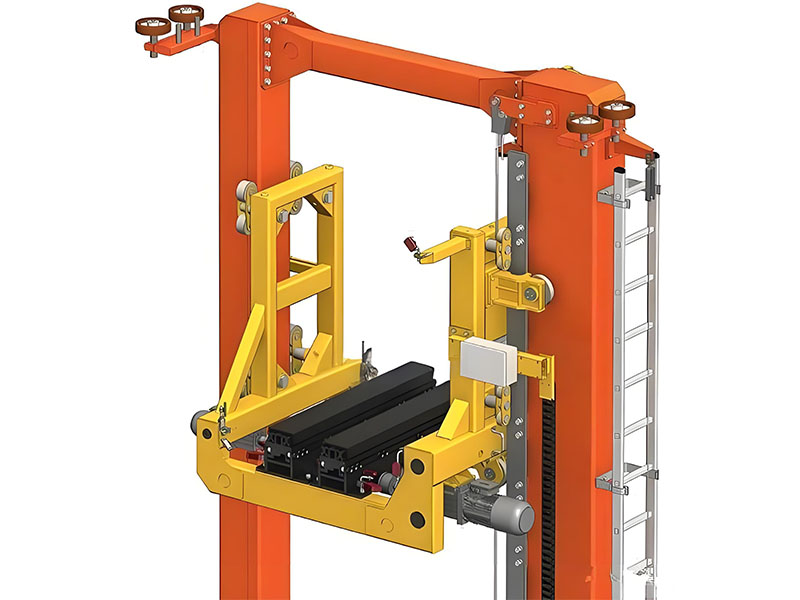

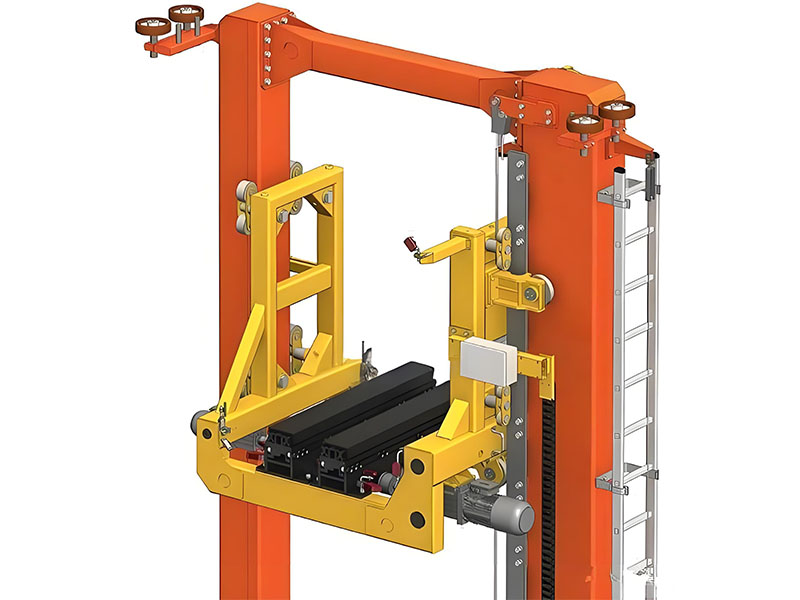

The newly built automated three-dimensional warehouse (AS/RS) by XX International Logistics in North China is the core node of its intelligent logistics network. The 12 aisle stacker cranes in the warehouse are responsible for the automated storage and retrieval of all palletized goods. They run at a speed of 5 meters per second between 24 meter high shelves, with a positioning accuracy requirement of up to ± 1 millimeter. They are the “main artery” that determines the throughput capacity and reliability of the entire warehouse. However, during the months long intensive debugging and trial operation phase, the stability and durability issues of the stacker crane’s walking wheels have become prominent bottlenecks restricting the system’s production capacity.

Wheel challenges and core requirements faced by stacker cranes

The chief mechanical and electrical engineer of the project pointed out that as the core execution equipment of the automated three-dimensional warehouse, the performance requirements of the walking wheels of the stacker crane far exceed those of ordinary storage vehicles, making it the ultimate industrial application:

1. Millimeter level repetitive positioning accuracy challenge

The core performance indicator of a stacker crane is repeatability accuracy. After long-term high-speed operation, original steel wheels or ordinary polyurethane wheels will experience uneven wear, resulting in micrometer level changes in wheel diameter. This will be amplified mechanically, ultimately causing cumulative deviation in the vertical stopping position of the forks. In severe cases, frequent system calibration is required, which affects the continuity of operations

Corresponding requirements: The walking wheel must have “extraordinary dimensional stability and wear uniformity” to ensure minimal changes in wheel diameter throughout its entire lifecycle, and to guarantee the long-term reliability of positioning accuracy from a physical perspective.

2. Vibration and noise control under high-speed heavy load

During the start stop process of the stacker crane with an acceleration of up to 0.5m/s ², the impact between the walking wheels and the steel guide rails will generate vibration and noise. Excessive vibration can be transmitted to the columns and cargo platforms, affecting the structural lifespan and cargo safety; The noise creates reverberation in the enclosed warehouse, deteriorating the working environment. ”

Corresponding requirements: The wheel material should have “excellent damping characteristics and elastic modulus”, which can effectively buffer the impact during high-speed operation, reduce vibration transmission and operating noise.

3. Long life demand under extreme working conditions

Our stacker crane is designed to operate continuously for 7×24 hours, with a theoretical annual mileage of over 3000 kilometers. The wheels bear several tons of load for a long time and frequently experience cyclic impacts from the rail joints at high speeds. Early failure of any wheel could result in the entire tunnel being shut down, causing significant economic losses. ”

Corresponding requirements: The walking wheels need to have “ultimate dynamic load-bearing capacity, impact fatigue resistance, and ultra-high wear resistance”, and the target service life should match the equipment overhaul cycle (usually 3-5 years).

Customized polyurethane wheel solution for stacker crane

Faced with this series of rigorous challenges, we have formed a specialized technical team and collaborated with our clients to develop the “AS/RS Ultra Series” polyurethane wheel set solution for stacker cranes.

Solution 1: Ultra high precision wheel diameter control and homogeneous material technology

To ensure positioning accuracy, we control from the source:

Precision manufacturing process: high-precision molds and constant temperature vulcanization process are used to ensure that the diameter tolerance of a single wheel is controlled within ± 0.1mm, and the matching error of the same group of wheel diameters is less than 0.05mm.

Homogeneous wear-resistant formula: A special homogeneous polyurethane formula has been developed, which has a highly uniform internal structure, ensuring that the wear rate of the entire tread is consistent during long-term wear, effectively avoiding the problem of wheel diameter roundness caused by eccentric wear.

Solution 2: Vibration damping design for layered composite structures

To suppress vibration and noise, we innovatively adopted a composite structure that combines rigidity and flexibility:

Three layer composite design: The inner layer is a high-strength metal wheel core, ensuring rigid support; The middle layer is a high damping elastic polyurethane transition layer, specifically designed to absorb high-frequency impact energy; The outer layer is a highly wear-resistant working surface. This structure reduces the impact acceleration by more than 40%.

Low noise tread profile: Optimize the curvature radius of the wheel tread to form the optimal contact area with the guide rail, reducing wind shear noise and friction howling during operation.

Solution 3: Enhanced dynamic load-bearing and anti fatigue formula

To meet the demand for ultra long lifespan, we have strengthened both materials and structures:

1. Dynamic Load Enhancement: Adopting high elastic modulus and low heat generation polyurethane composite materials, its dynamic load capacity is 30% higher than standard products, with low internal temperature rise and minimal performance degradation under high-speed cyclic loading.

2. Impact and fatigue resistance: Implanting a special fiber-reinforced network into the polyurethane matrix significantly improves the crack propagation resistance (fatigue resistance) of the wheel body under repeated impacts, eliminating the risk of brittle fracture.

3. Comprehensive life commitment: Provide a “service life guarantee” synchronized with the first major overhaul cycle of the equipment for this series of products.

Implementation effect and value reflection

After all stacker cranes were equipped with new wheels and calibrated, the system underwent a 6-month full load pressure test, and the performance data fully met the standards

System stability: The standard deviation of the repetitive positioning accuracy of the stacker crane remains within ± 0.5mm, without the need for mid-term calibration, and the system availability is increased to over 99.95%.

Operating environment: The operating noise in the tunnel is reduced by 8-10 decibels, the equipment vibration value is reduced by 50%, and the fatigue loss of structural components is significantly reduced.

Maintenance cost: Wheel maintenance has changed from “unplanned replacement” to “predictive maintenance synchronized with equipment overhaul”, reducing the average annual maintenance cost of a single roadway by more than 70%.

Return on investment: The expected payback period for this solution is less than 10 months due to the increased throughput caused by stable accuracy and reduced downtime.

Customer reviews

This is a crucial technical decision for us, “Liu concluded.” The wheels of the stacker crane may seem simple, but they are actually the cornerstone of accuracy. The ‘AS/RS Ultra series’ not only solves our initial accuracy drift and vibration problems, but also demonstrates unexpected durability, giving us confidence in the stable operation of this expensive automation system for the next five to ten years. It consolidates our investment value from the bottom up. ”

Define core walking standards for automated warehousing

In the pursuit of efficiency and reliability in automated logistics systems, deep exploration and customized innovation of basic component performance are key to unleashing the potential of the system. We are committed to becoming a strategic partner for high-end logistics equipment manufacturers and operators, providing solid guarantees for the “last millimeter” accuracy and “over 10000 hours” lifespan of automation systems with advanced material technology and profound scene understanding.

YALIDE Technology Co., Ltd. – High end logistics equipment polyurethane wheel system solution supplier

YALIDE >

Customer Stories> How to achieve performance leap in automated warehouses through polyurethane wheels

YALIDE >

Customer Stories> How to achieve performance leap in automated warehouses through polyurethane wheels

Monday to Friday 8:00-17:00

Monday to Friday 8:00-17:00

Telephone:

Telephone:  Email:

Email:  whatsApp:

whatsApp: