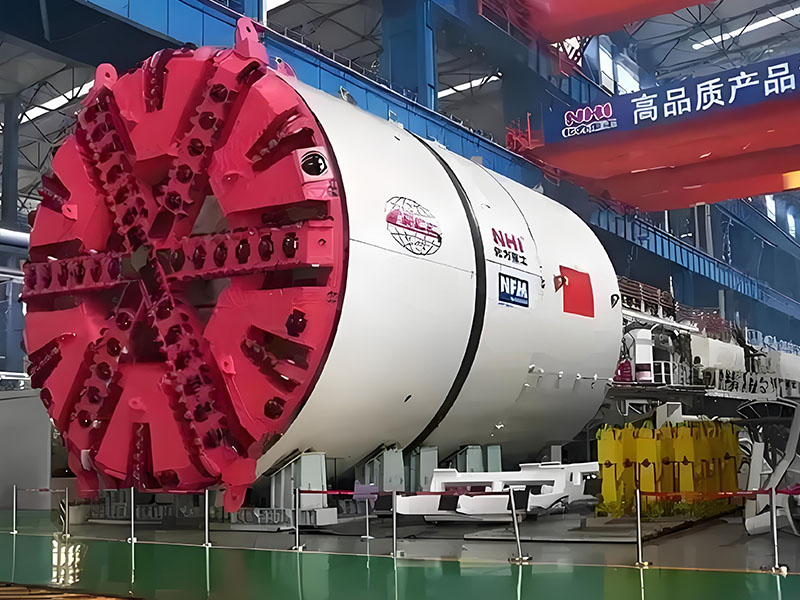

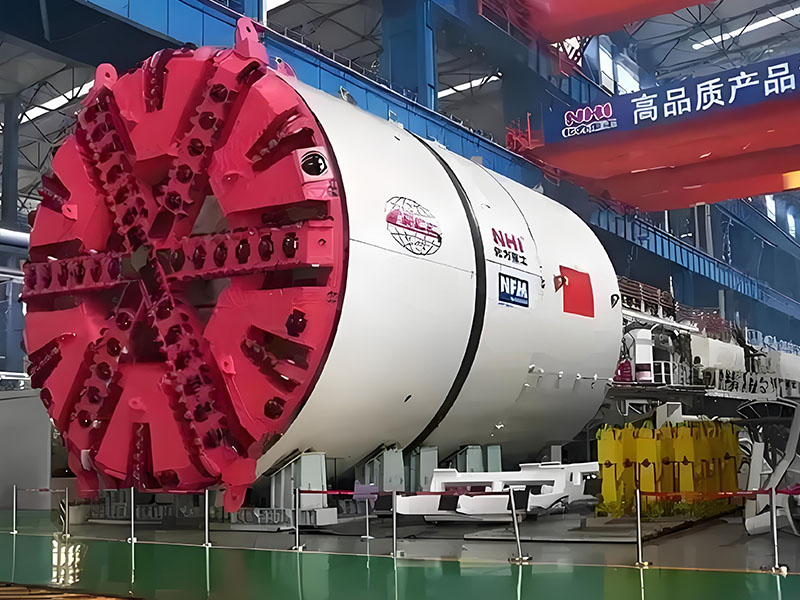

Project Background

XX Rail Transit Group is undertaking the construction of a key section of the urban subway line 12, which has complex geological conditions and requires the use of a 6.8-meter diameter earth pressure balance shield machine for excavation. In a 25 meter deep underground tunnel, a massive supporting system consisting of over 40 trolleys is responsible for key tasks such as pipe transportation, slag transportation, and power supply. These heavy-duty trolleys need to operate continuously on narrow, damp, and temporary tracks filled with debris, and the reliability of their walking wheels directly affects the safety and efficiency of the entire excavation project.

The wheel challenge faced by shield tunneling machines

1. Collapse deformation under extreme heavy load

Each car weighs over 30 tons and is supported by four wheels. The original nylon wheels have undergone significant plastic deformation under long-term heavy pressure, resulting in reduced wheel diameter and abnormal stress on the pipelines connecting multiple cars. Multiple hydraulic oil pipe ruptures have occurred.

2. Slip and rail gnawing in mud environment

The humidity inside the tunnel is saturated, and there is inevitably a mixture of lubricating grease and mud on the track. Traditional material wheels have severely insufficient grip, causing motor-driven trolleys to slip and spin when starting, and at bends, there is a phenomenon of ‘rail gnawing’ where the wheel rim presses against the steel rail, resulting in severe track wear

3. Abnormal wear under the impact of slag soil

Despite cleaning measures, fine debris still enters the wheel rail contact surface. These debris containing quartz sand become strong abrasives, and the surface of ordinary wheels is quickly cut into grooves, requiring replacement in less than 200 hours, seriously affecting construction continuity

Our solution

Our engineering team conducted on-site measurements in the tunnel, collecting key data such as track cross-section, soil composition, and load distribution. We have launched the “Shield Pioneer” series of heavy-duty polyurethane wheels:

Option 1: High rigidity core reinforcement structure

Embedded steel wheel hub: an integrated wheel hub formed by forging, mechanically interlocked with polyurethane through a specially designed concave convex structure

Layered composite design: The inner layer is made of ultra-high hardness polyurethane (Shore D grade) as the supporting skeleton, and the outer layer is made of highly elastic and wear-resistant materials, providing necessary cushioning while ensuring load-bearing capacity

Load bearing verification: According to laboratory tests, the structure has undergone a continuous 720 hour static load of 10 tons, with a permanent deformation of only 0.8%

Option 2: Adaptive tread pattern and material formula

Self cleaning tread design: Innovative use of a central protrusion and diagonal drainage grooves on both sides, generating centrifugal force to actively discharge foreign objects from the contact surface during rotation

High humidity grip formula: polar molecular materials are added to the polyurethane base material to increase the friction coefficient in a humid environment, with a measured wet friction coefficient of 0.28

Anti oil treatment: The wheel surface undergoes special surface treatment to form an anti oil coating, preventing slipping caused by grease adhesion

Plan 3: Multi layer composite wear-resistant system

Matrix reinforcement: Uniformly disperse diamond sand micro particles (particle size accurately calculated) in the polyurethane matrix to form the first line of wear-resistant defense

Surface treatment: The wheel surface has undergone special hardening treatment, achieving a surface hardness of Shore A95 while maintaining good elasticity

Tear resistant design: Add aramid fiber reinforcement layer at the wheel rim to resist lateral shear force at bends and completely solve the problem of “rail gnawing”

Implementation effect

After the first batch of 20 sets of wheels were installed and used for 800 hours, we conducted a comprehensive evaluation together with the construction party

Load stability: The smoothness of the trolley’s operation has been significantly improved, and the failure rate related to hydraulic pipeline vibration has decreased by 90%

Track protection: The problem of abnormal rail wear has been eradicated, and it is expected that the track replacement cycle will be extended by three times

Service life: After 800 hours of high-intensity use, the wear on the wheel surface is only 1.2mm, and it is expected to fully meet the 1500 hour usage target

Traction efficiency: The response speed of the motor-driven trolley to start and stop has been improved, and the overall energy consumption of the system has been reduced by about 5%.

Industry significance and prospects

The shield tunneling method is developing towards longer distances, larger diameters, and more complex geological conditions, which puts higher demands on the reliability of the supporting systems. This case proves that under extreme heavy load and harsh environmental conditions, the deeply customized polyurethane wheel solution can fundamentally improve the performance of key moving parts and provide solid guarantees for the stable operation of large heavy-duty equipment.

We will continue to deepen our expertise in the field of special engineering machinery, making innovative material solutions a reliable support for the high-quality development of global infrastructure.

YALIDE >

Customer Stories> How to solve the transportation problem of the supporting system behind shield tunneling machine with polyurethane wheels

YALIDE >

Customer Stories> How to solve the transportation problem of the supporting system behind shield tunneling machine with polyurethane wheels

Monday to Friday 8:00-17:00

Monday to Friday 8:00-17:00

Telephone:

Telephone:  Email:

Email:  whatsApp:

whatsApp: