About us

Yalide is a polyurethane wheel manufacturer, providing customers with the perfect roller/axle/wheel product system solutions

YALIDE > About us

YALIDE > About us

Yalide Technology Co., Ltd. is a national happy technology enterprise with years of experience in the development, molding, manufacturing, and testing of polyurethane and rubber materials. The company focuses on the research and development of polymer material technology, while combining various production processes and experienced technical personnel to provide customers with complete system solutions for roller/shaft/wheel products.

We produce and research rubber wheels and rollers, including polyurethane coated wheels, polyurethane rubber rollers, rubber rollers, coated rollers, coated bearings, metal shafts, mirror rollers, spray rollers, etc., mainly used in intelligent logistics equipment, intelligent production lines (automotive production lines, lithium battery production lines, semiconductor production lines, LCD panel production lines, photovoltaic manufacturing production lines, and other automated production lines), etc.

In order to meet the needs of customers in different industries, we continuously develop and improve material technology, perfect and expand more application projects to cope with the growing market demand and challenges. For over 20 years, our engineers have been working closely with renowned material laboratories in China to develop and composite materials, including NDIthane, Loathane, Rollthane, Fricthane, Electrhane, and MDIthane, which are elastic materials.

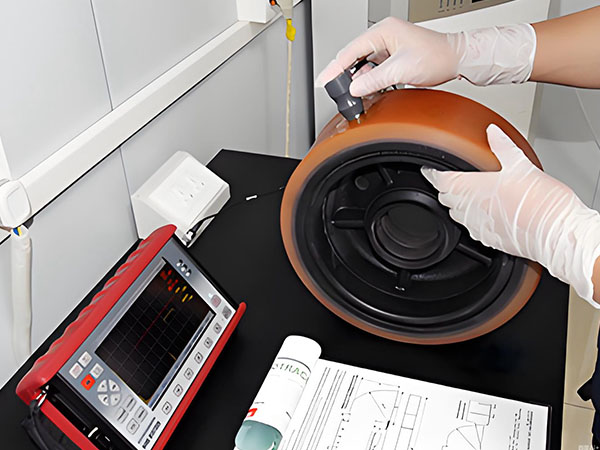

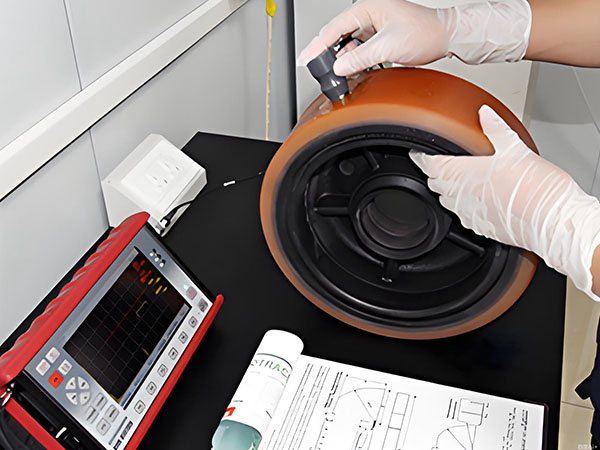

Ultrasonic Flaw Detector

Reaction kettle

Polyurethane Casting Line

Wheel Oven

Wheel Core Cleaning Line

Automatic Glue Dispensing Machine

Sandblasting Machine

We offer a wide range of cast-iron, steel, aluminum and other hubs. All hubs are machined inside our turning and machining centers. The finished hub will pass the inspection, including specification, material stress, concentricity, etc.

Clean the wheel core and remove the oil stain on the surface to obtain a clean surface and ensure the bonding effect of glue. Sand blasted for improved adhesion. Finally, the adhesive is applied to the rim surface.

Heat the hub and die, activate the adhesive on the hub surface, and cast the polyurethane material into the die on the rotary table by center point pouring to avoid air bubbles. Demould after curing for 30 minutes.

Post-sulphurization is the basic process of manufacturing. After demoulding, the wheels will be put into the curing chamber under the specified conditions. Polyurethane properties will remain stable and optimum until all chemical reactions are completed.

We have obtained certifications for systems such as ISO9001:2015, ISO 9001, ISO 14001, and IATF 16949, with the aim of ensuring high-quality standards in our field and manufacturing processes, in order to provide customers with the best service support and technical indicators. All processes, products, and facilities are recorded and traceable.

Strict quality management system;

Standardized internal management, effectively following all procedures and standards;

Scientific computation and continuous improvement;

All processes, products, and facilities are recorded and traceable.

Engineers are familiar with and proficient in using various modern testing equipment, such as dynamic fatigue testing machines, manufactured according to Din En 12524-12533 standards, with a maximum load of 40KN on a rotating testing platform. It can test the fatigue resistance of wheels at a speed of 20KM/H, as well as perform endurance tests, obstacle tests, rolling resistance tests, etc. The entire process is monitored by a computer. Other testing equipment includes: hardness tester, wear tester, tear and tensile tester, high and low temperature laboratory, ultraviolet and ozone climate chamber, resistance NCO、DMA、 Dynamic balancing, electric microscope, servo hydraulic testing machine, servo hydraulic horizontal wheel testing machine, ultrasonic flaw detector, anti wet sliding friction tester, etc.

We also use dedicated FEM modules for strength calculations and load condition simulations. This allows us to check the key parameters of the wheels through a computer. Using FEA (Finite Element Analysis) computer numerical analysis programs to solve complex problems in many fields of engineering and motion mechanics, such as structural analysis (stress, deflection, vibration, and fatigue), thermal analysis (steady-state and transient), and fluid dynamics analysis (laminar and turbulent flow).

Code of Conduct

Code of ConductDare to challenge and innovate, unite, be honest, shoulder responsibilities, and implement them to the end; Always committed to providing customers with truly outstanding products.

Sense of Worth

Sense of WorthPersonal value and corporate value are jointly realized, and every effort is made to contribute to the development of society.

Using the highest quality materials, the latest equipment and technology, and rigorous craftsmanship, we have never forgotten our original intention for many years, which is to insist on manufacturing truly outstanding products that meet the needs of customers.

We focus on designing and manufacturing high-quality wheels, and have always relied on our core competitiveness and position to provide customers with high-quality services.

In order to respond quickly and help customers cope with the challenges of polyurethane special wheel products, we utilize material technology and engineering capabilities to provide value-added customized services, providing guarantees for rapid prototyping, small batch production, and automated mass production. Customized services include material development and wheel design, welded wheel rim construction, tool production and testing, etc. Replacing rubber related products with polyurethane not only achieves higher wear resistance, but also improves efficiency, reduces costs, and enables customers to achieve higher economic benefits.