Mining Casters

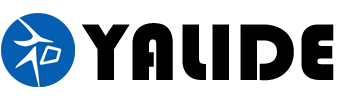

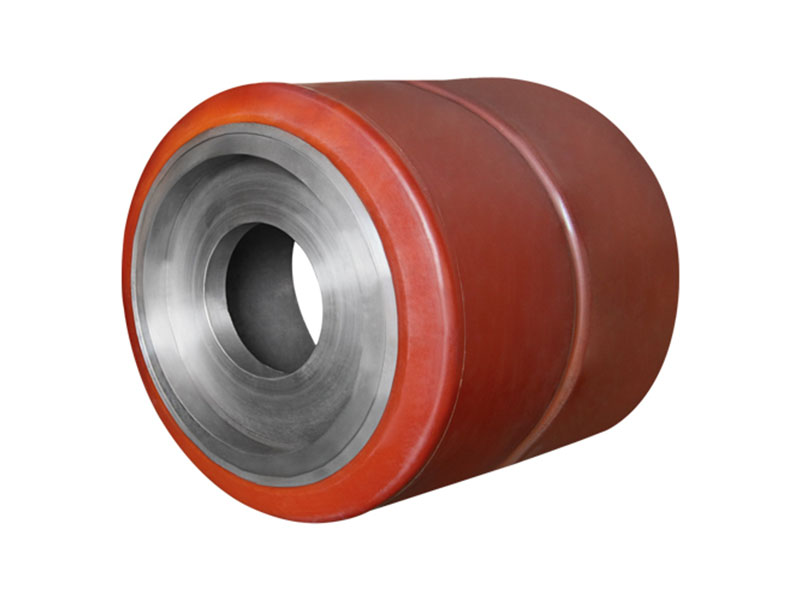

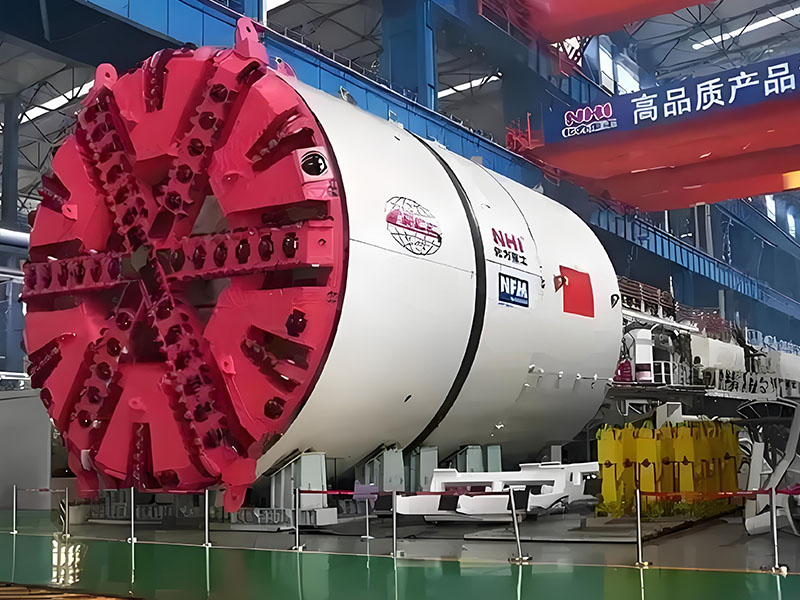

Mining casters are key components of mining transportation equipment that require special requirements such as high strength, wear resistance, and explosion resistance. Currently, polyurethane is the most commonly used material. Polyurethane casters are wear-resistant and corrosion-resistant, suitable for wet underground environments, and have good load-bearing capacity NDI polyurethane heavy-duty casters are composed of heavy-duty metal brackets, high load bearings, steering ball bearings, and NDI polyurethane tread materials. They adopt a dual bearing structure of tapered roller bearings and ball bearings, which disperses the load gravity and provides flexible steering, increases the contact area of the load, reduces the impact force of the load, and minimizes the force required to change direction and the lateral stress on the ground facing the tire. They operate more flexibly and enhance the service life of the tire.

READ MORE >>

Monday to Friday 8:00-17:00

Monday to Friday 8:00-17:00

Telephone:

Telephone:  Email:

Email:  whatsApp:

whatsApp: