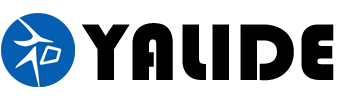

New energy manufacturing

The production line of new energy products (lithium batteries, photovoltaic panels) uses polyurethane wheels, which are dust-free, anti-static and corrosion-resistant, and can well ensure the cleanness of the production line. The polyurethane material has very good wear resistance and impact resistance, and also has strong bearing capacity, which can well meet the needs of the new energy manufacturing production line.

Monday to Friday 8:00-17:00

Monday to Friday 8:00-17:00

Telephone:

Telephone:  Email:

Email:  whatsApp:

whatsApp: