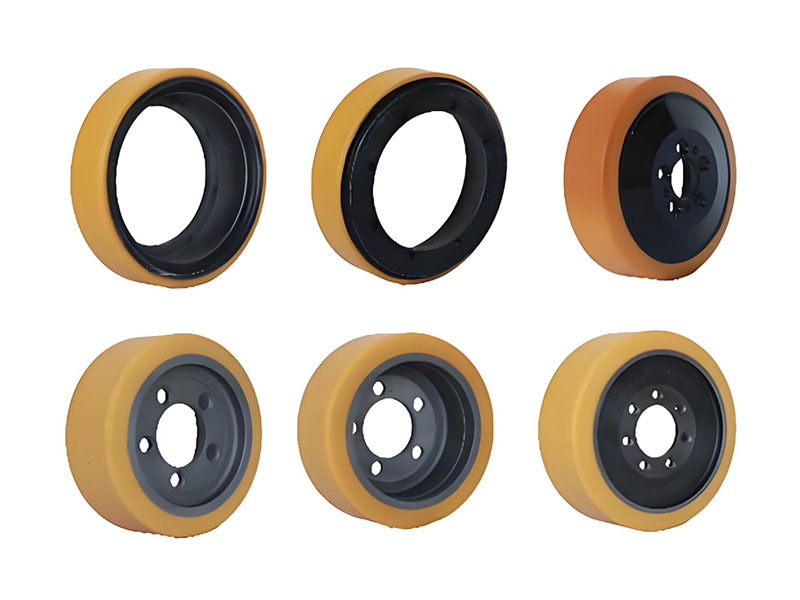

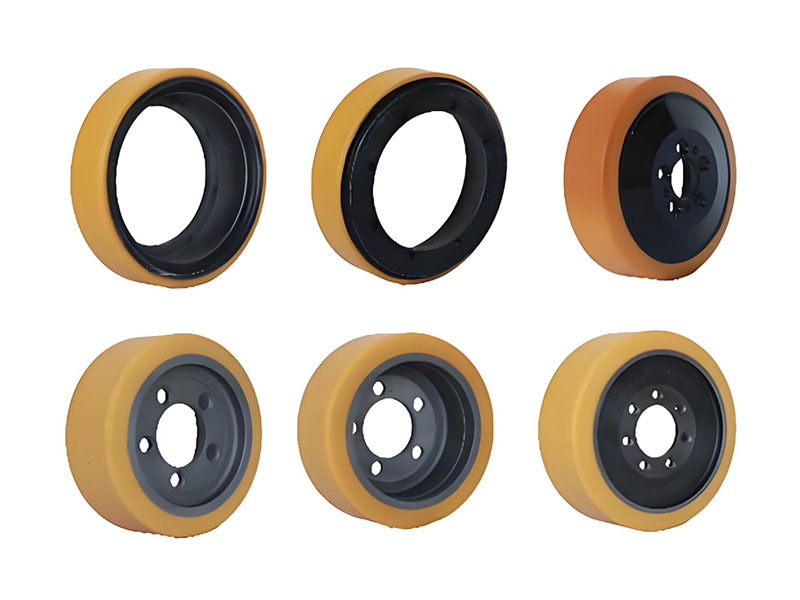

As a manufacturer deeply rooted in the field of polyurethane wheel manufacturing for many years, we have been closely monitoring the pulse of industry development with our dual manufacturing base layout in China and Vietnam. In recent years, with the advancement of logistics automation and intelligent warehousing, forklifts, as the core equipment for material handling, are facing unprecedented challenges in their key components – polyurethane wheels. How to address these challenges and promote product upgrades has become a common focus of attention in the industry.

The four core challenges currently faced by polyurethane wheels for forklifts

1. Durability challenges under high-intensity working conditions

In modern warehousing and logistics scenarios, forklifts operate frequently, carry large loads, and often require long-term operation in environments with rough surfaces, large temperature differences, or chemical residues. This places extremely high demands on the wear resistance, tear resistance, and aging resistance of polyurethane wheels. Traditional formula polyurethane wheels are prone to early wear, chipping, cracking and other problems, which directly affect the service life of equipment and operational safety.

2. Adaptability requirements for precision application scenarios

There are significant differences in performance requirements for fork shaped wheels among different industries. For example, the food and pharmaceutical industry requires wheels to have antibacterial and pollution-free properties; The electronic workshop requires high anti-static and low-noise wheel sets; Cold storage environments have strict standards for low-temperature toughness. A single type of product can no longer meet the needs of market segmentation, and customized and scenario based solutions have become an inevitable trend.

3. Environmental Protection and Sustainable Development Pressure

The increasingly strict environmental regulations worldwide have raised higher requirements for the volatile organic compound (VOC) emissions, recyclability, energy consumption, and waste disposal of polyurethane materials during production. At the same time, downstream users are increasingly concerned about the environmental performance of products throughout their lifecycle, and green manufacturing has become the basic threshold for industry entry.

4. Cost control and supply chain stability

The fluctuation of raw material prices, increased uncertainty in international logistics, and rising labor costs continue to squeeze the profit margins of manufacturing enterprises. How to optimize cost structure and build a robust and efficient supply chain system while ensuring quality is an operational challenge that enterprises must face.

Our dual base collaborative solution

Based on our manufacturing layout in China and Vietnam, we have proposed systematic solutions to the above challenges through technology research and development, production optimization, and supply chain integration.

1. Material innovation and process upgrading

Our research and development center has launched a new generation of high-performance polyurethane elastomer materials, which have significantly improved their wear resistance index (Akron wear reduction of over 30%) and tear strength through molecular structure modification. At the same time, we adopt intelligent temperature control vulcanization process and precision casting technology to ensure uniform internal structure of the product and prevent defects from occurring. The laboratories of China and Vietnam have closely collaborated to develop a series of formulas with stronger environmental adaptability for different climate conditions such as high temperature, high humidity, and low temperature drying.

2. Scene customization and rapid response

With the flexible production lines of our two factories, we are able to provide customers with efficient customized services. Whether it is different hardness requirements (such as precise grading of Shore A 85 °~95 °), special color identification, or special functions such as conductivity/anti-static, oil resistance, acid and alkali resistance, rapid sampling and mass production can be achieved. The Vietnamese base focuses more on standard products and customized needs in the European and American markets, while the Chinese base deeply cultivates the Asia Pacific market and undertakes high-end research and development, forming synergy and complementarity.

3. Green Manufacturing and Circular Design

We fully implement green factory standards and use environmentally friendly polyether polyols and low volatility modified MDI systems to reduce harmful substances from the source. At the same time, we are developing polyurethane wheel recycling technology and exploring the reuse path of old wheel crushed materials in non critical components. Vietnamese factories have already utilized 40% of local renewable energy, while Chinese factories have achieved a 20% reduction in energy consumption per unit product through process optimization.

4. Supply chain optimization and cost control

The dual base layout gives us stronger supply chain resilience. Implement a multi regional procurement strategy for key raw materials and establish a safety stock buffer. By vertically integrating some raw material pretreatment processes and optimizing production capacity allocation between China and Vietnam, we have reduced overall operating costs and been able to provide customers with more stable delivery times and competitive prices.

Looking ahead to the future: intelligent and integrated services

Faced with the trend of Industry 4.0, we are integrating sensing technology into wheel design and developing intelligent wheel sets that can monitor wear, load, and temperature in real time, providing data support for preventive maintenance. At the same time, we are committed to transforming from a “product supplier” to a “solution provider”, providing customers with full cycle services including wheel selection, life prediction, and replacement guidance.

As a polyurethane wheel manufacturer rooted in China and Vietnam, we deeply understand that challenges are opportunities. Through continuous innovation, dual base collaboration, and green intelligent manufacturing, we are not only able to provide customers with more reliable, efficient, and environmentally friendly forklift polyurethane wheel products, but also willing to work together with industry partners to promote progress and development in the field of material handling.

About Us

We are a professional manufacturer of high-performance polyurethane wheels, with two modern production bases in China and Vietnam. We are committed to providing durable, safe, and environmentally friendly wheel solutions for forklifts, logistics equipment, and industrial vehicles worldwide.

YALIDE >

News Content>Industry News> Challenges and Upgrades in the Polyurethane Wheel Industry for Forklifts

YALIDE >

News Content>Industry News> Challenges and Upgrades in the Polyurethane Wheel Industry for Forklifts

Monday to Friday 8:00-17:00

Monday to Friday 8:00-17:00

Telephone:

Telephone:  Email:

Email:  whatsApp:

whatsApp: