In the vast mines of China and the emerging mineral resource areas of Vietnam, heavy transportation equipment shuttles day and night, bearing the vital responsibility of resource transportation. As someone who is deeply involved in the field of polyurethane wheel manufacturing and has laid out production bases in both China and Vietnam, we are well aware that under these extremely harsh working conditions, a reliable wheel set is not just an ordinary component, but the cornerstone for ensuring efficiency, safety, and cost control. Polyurethane wheels used in mines are facing unimaginable challenges in ordinary fields, and are also giving rise to exclusive technological innovations.

Facing the “purgatory” level challenge of extreme working conditions in mines

Challenge 1: Double sided Strike with Super Wear and Sharp Piercing

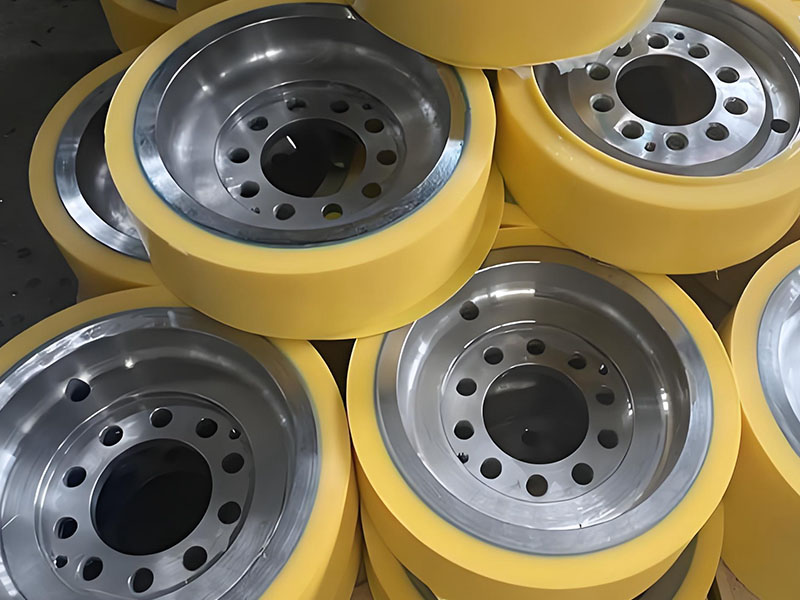

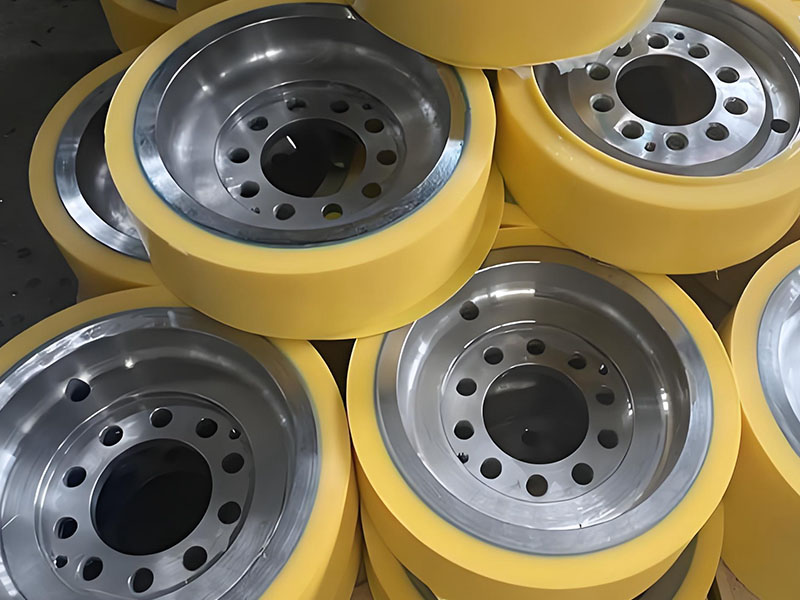

The mining road surface is covered with sharp gravel, slag, and irregular hard objects, and ordinary wheel surfaces are easily cut, scratched, or even pierced. At the same time, continuous heavy load handling and long-distance driving have led to an exponential increase in the wear rate of the wheel surface. Wear resistance and tear resistance cannot be a trade-off here, but must be an absolute performance that combines both.

Challenge 2: “Extreme Testing” of Heavy Load Impact and Dynamic Load

Mining vehicles have extremely heavy loads, frequent starting and stopping, and often operate on slopes and bumpy roads. The wheelset not only needs to withstand static heavy pressure, but also needs to effectively buffer dynamic severe impacts, prevent delamination, cracking or instant failure caused by internal structural fatigue, which puts forward extreme requirements for the elastic recovery capacity, bearing strength and bonding process of polyurethane materials with the wheel core.

Challenge 3: The “invisible erosion” of complex chemical environments and temperature differences

The possible presence of oil stains, acidic or alkaline substances in the mining environment, as well as the huge temperature differences caused by day night alternation and regional differences, can accelerate the aging, hardening or performance degradation of polyurethane materials, shortening the service life of the wheel set.

Challenge 4: Precise Balance between Safety Red Line and Comprehensive Operating Costs

Mine safety is above all else. Any unexpected malfunction of the wheelset may lead to serious safety accidents. At the same time, under enormous operational pressure, customers are not only concerned about the price of a single wheel, but also about the frequency of replacement, equipment downtime, and maintenance costs throughout its entire lifecycle. Durability is directly related to overall economic benefits.

Our solution: professional wisdom born for mines

Based on the deep research and development capabilities of our Chinese base and the agile manufacturing capabilities of our Vietnamese base, we have built a three-dimensional solution system for extreme working conditions in mines.

1. Core Material Revolution: Triple Protection Shield Armor

Our independently developed “Mineral Shield” series of polyurethane elastomers is the core of the answer:

-First priority: super wear-resistant layer. By using special wear-resistant additives and polymer network reinforcement technology, Akron’s wear is much lower than the national standard, ensuring “less wear” on gravel roads.

-Second layer: tear resistant and stab resistant layer. Optimize the cohesion and toughness of materials, even in the face of sharp impacts, to effectively resist the spread of fragmentation and prevent local damage from causing overall failure.

-The third layer: environmental stability layer. The formula has excellent oil resistance, acid and alkali resistance, and wide temperature range (-40 ℃ to+80 ℃) adaptability, ensuring stable performance in complex environments without cracking or hardening.

2. Structural design and craftsmanship essence: combining rigidity and flexibility, as solid as gold soup

-Reinforced inner core structure: High strength steel wheel core is used, and the web design is optimized to ensure no deformation under ultimate load. The unique surface treatment process and high-performance adhesive achieve a “molecular level” bonding between polyurethane and metal wheel cores, completely eliminating delamination.

-Patent pattern design: designed for mining road surfaces, featuring deep patterns and large chip grooves to enhance grip and self-cleaning ability, while improving cushioning and shock absorption performance to protect equipment and drivers.

3. Dual Base Collaborative Manufacturing: Quality, Efficiency, and Supply Assurance

China Base: As the “mother factory” for technology research and development and high-end products, we focus on the production and complex process research of top-level products such as the “Mining Shield” series.

Vietnam Base: With cost and location advantages, it efficiently produces standardized mining gear trains and quickly responds to the demand of the Southeast Asian mining market. The two regions share a quality control system to ensure globally consistent excellence in quality.

Supply chain resilience: The dual base layout disperses supply chain risks, with dual line reserves of key raw materials, ensuring stable and reliable supply guarantees for customers even in the face of global fluctuations.

4. Value Beyond Products: From Wheels to Solutions

We provide not only wheel sets, but also value-added services for the full lifecycle management of mining wheel sets. Based on big data analysis of different types of minerals, vehicle models, and operating conditions, we can recommend the optimal model for customers and provide wear monitoring guidance, helping customers predict maintenance cycles, plan spare parts inventory, minimize unexpected downtime, and reduce overall operating costs.

Outlook: Towards Intelligence and Sustainable Development

In the future, we are exploring the possibility of embedding sensing modules into heavy-duty wheelsets to monitor tire pressure, temperature, load, and wear data in real-time. Through IoT platforms, we can provide early warning of risks and achieve a leap from “preventive maintenance” to “predictive maintenance”. At the same time, we continue to invest in the research and development of environmentally friendly materials, committed to finding a balance between ultimate performance and green manufacturing, and contributing to the sustainable development of the mining industry.

On the land of strength and resilience witnessed by the mining industry, we are willing to use the technological ingenuity of the Sino Vietnamese dual base to create every polyurethane wheel worth entrusting. We are not only suppliers of components, but also guardians of your transportation safety and operational efficiency. Choose a profession, choose reliability, let us jointly bear the weight of the mine and sail towards an efficient and stable future.

About Us

We are an enterprise with significant influence in the global polyurethane industrial wheel manufacturing field, with advanced research and production bases established in China and Vietnam. Our mining specific wheel series products, with excellent wear resistance, impact resistance, and environmental adaptability, serve many large mining groups around the world and are a trusted partner for heavy transportation equipment.

YALIDE >

News Content>Industry News> The Challenge and Innovation Path of Mining specific Polyurethane Wheels

YALIDE >

News Content>Industry News> The Challenge and Innovation Path of Mining specific Polyurethane Wheels

Monday to Friday 8:00-17:00

Monday to Friday 8:00-17:00

Telephone:

Telephone:  Email:

Email:  whatsApp:

whatsApp: